OMNI-VISION ARCHITECTURE

█

Training a model is easy. Deploying it is hard. I architect end-to-end Computer Vision pipelines—from CVAT Data Labeling to YOLOv8 Training to FastAPI Production Deployment.

Slices high-res image into grid to maintain small-object visibility.

Merges detections using Non-Maximum Suppression (NMS).

"""

LIFECYCLE // DATA TO DEPLOYMENT

Rapid Annotation

Designing semi-automated labeling workflows using CVAT and auto-labeling scripts to speed up dataset creation by 500%.

Custom Architecture

Fine-tuning YOLOv8 and PyTorch models. Implementing Tiled Inference (SAHI) to detect microscopic defects on 4K resolution images.

Production API

Wrapping models in high-performance FastAPI backends with async queue management to handle concurrent video streams without crashing.

PROJECT OPTIC-GUARD

Manufacturing Defect Detection System

The client had 4K resolution images of assembly lines. Standard YOLO models failed because they downsized the image, making small defects invisible.

Implemented Tiled Inference—slicing the 4K image into 12 smaller "tiles" to maintain resolution.

Each tile is processed in parallel by the model.

A custom algorithm merges the detection coordinates back onto the original 4K frame, removing duplicate overlaps (NMS).

Real-time detection of <2mm defects with zero latency lag.

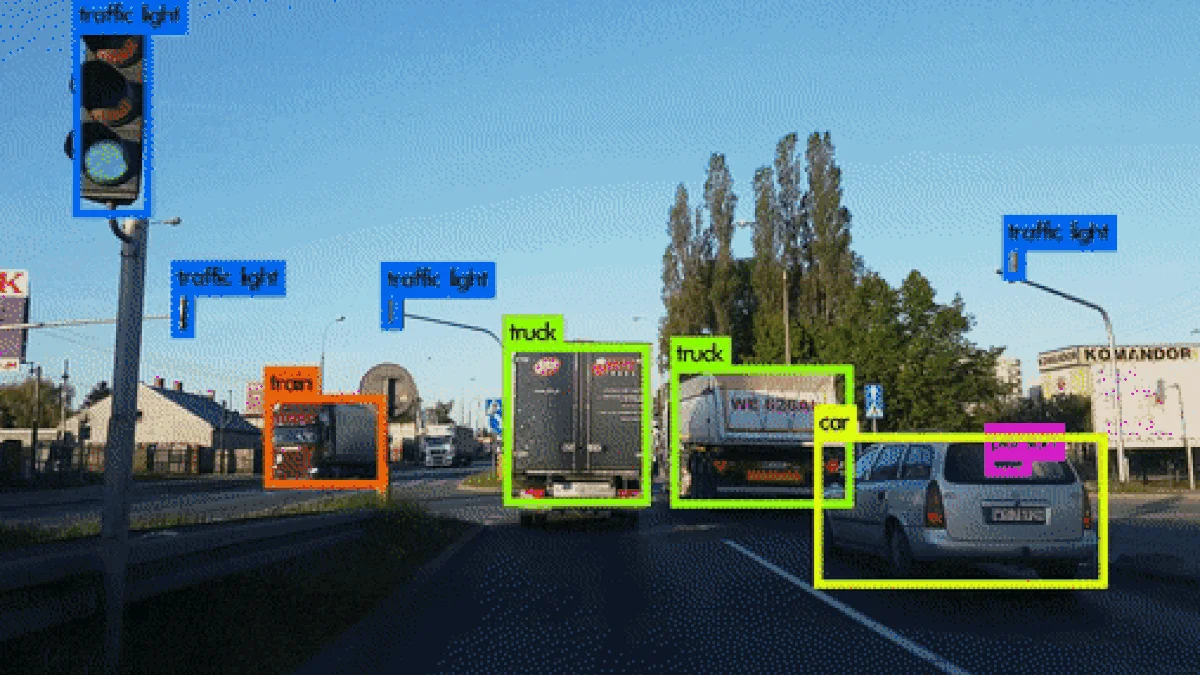

Real-time YOLOv8 Detection

PROJECT NEURAL-FORGE

Accelerated AI training dataset creation by 600%

The Challenge: Client needed 10,000+ labeled images for defect detection, but manual annotation was too slow and expensive.

The Solution: Engineered an AI co-pilot using YOLOv8 that auto-generates bounding boxes. Humans simply verify, cutting manual effort by 85%.

The Impact: Reduced labeling time from 3 mins to 10 seconds/image, saving $50K+ annually.

PROJECT PIXEL-PERFECT

High-Fidelity Retail Instance Segmentation

The Challenge: Retail analytics requires more than just bounding boxes. To calculate "Shelf Share", the client needed exact polygon masks for overlapping items on messy racks.

The Execution: I engineered a 99.5% IoU precision pipeline. Using CVAT and custom validation scripts, I delivered a COCO-compliant dataset that enabled fine-grained product differentiation.

PROJECT SYNTH-GEN

The Infinite Dataset: Procedural Training Data

The Bottleneck: Training CV models requires massive labeled datasets. Collecting and labeling 50,000 CAPTCHAs manually would take weeks and cost thousands.

The Solution: I engineered a Procedural Generation Engine using Python and OpenCV. It creates infinite unique CAPTCHA variations and automatically generates 100% accurate labels, enabling rapid model training.

ADVANCED CAPABILITIES

Detecting microscopic defects, scratches, or misalignments on assembly lines.

Tiled Inference (SAHI) for small object detection on 4K hardware.

Turning scanned PDFs and invoices into structured JSON data.

LayoutLM & PaddleOCR for complex table extraction (not just text reading).

Real-time monitoring for PPE (Hard Hats, Vests) or unauthorized zone intrusion.

Real-time RTSP stream processing with <50ms latency for immediate alerts.

Tracking foot traffic, dwell time heatmaps, and queue lengths.

Object Tracking (ByteTrack) to maintain identity across frames.

TECHNICAL FAQ

A: Negative. I utilize Transfer Learning (using pre-trained weights from YOLOv8/11). We can achieve high accuracy with as few as 50-100 labeled examples per class to start a prototype.

A: Affirmative. I optimize models using TensorRT and ONNX formats, allowing heavy neural networks to run smoothly on Jetson Nanos, Raspberry Pis, or local CPU servers without needing a $10,000 GPU cluster.

A: I build "Air-Gapped" capable containers. Your video feeds process locally (on-premise) or in a private cloud VPC. No data is sent to third-party APIs unless authorized.

TILED INFERENCE PIPELINE

Technical breakdown of the defect detection system

Powered By